Category

- ALL

- Screws

- Timer/ Deck screw

- Reduce Point Self-drilling Screws

- Hex Head Self-drilling Screws(Tek Screws)

- Countersunk/Flat/Pan head Self-drilling Screw

- Milling Point Self-drilling Screws

- Concrete Screws

- Zn-Al Capped Self-drilling Screws

- Stainless(ss 304) Capped Self-drilling Screws

- Wood/Chipboard Screw

- No5 Point Self-drilling Screws

- Type 17 Screws

- Head Painted Roofing Screws

- Drywall Screws

- Bolts and STUD

- Nuts

- Stamping

- CNC Turning

Reduce Milling Point Self-drilling Screw

- Milling point tip

- Roofing screws

- Steel truss

- Good performance for thick plate

-

Milling point self-drilling screw perform much better than traditional self-drilling screw. The drilling point is made by different milling cut. In our research, milling point self-drilling screw has better drilling speed, cutting ability and pull out force.

-

DIN, IFI, ISO, ASTM, ASME or according to customer's drawing and samples.

Material: Carbon steel: 1022, 1018

Gauge: #12 - #14, M5.5 – M6.3

Length: 1/2’’- 10’’, 12mm – 250mm

Drilling point: #3, #5 -

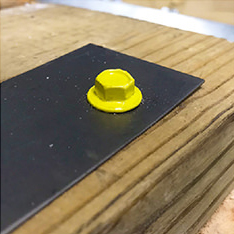

Milling Point Screw

(Replace "Structural Wood Screws")

The Milling Point Screw, or "MPS", is a 6.4mm diameter wood screw. With its high strength, the MPS is specifically designed to fasten 2-ply wooden pieces together such as plated trusses and solid wood engineered timber products.

Milling Point

The tail of the MPS is designed in such a way that when drilling into the edge of the wood, the torque can be reduced meaning that the wood will not be cracked.

Asymmetric Thread

The special angle design can increase tensile strength and enhance pull-out resistance in a variety of applications. The MPS does this through firmly clinching the plates together to

Corrosion Resistant

C3,C4 Ruspert Coating Salt Spray Test 1000, 2000 hrs Kesternich Test 15, 20 cycles

Ribs

The ribs of the MPS allow for the screw to sink cleanly into a firmly fixed position therefore, increasing its security onto wood.Common Applications

Truss

Solid wood

Steel+timber